SXKH Mold Cleaning Machine adopts national patent technology, using the principle of cavitation which needs to mix high-pressure air and high-pressure water together and release the mixture in the way of pulse. We can adjust the pressure and pulse frequency, according to the clogging condition of different mold, to strike scale, rust and other obstacle in the inner wall of pipeline. The direction that the mixture is released could be change so when the machine is operating, the inner wall of the mold pipeline will be repeatedly washed and stricken in both directions, so that the scale and rust on the inner wall can be removed. Finally the separated scale and rust will be collected and discharged.

| Model |

CMG-11 |

CMG-15 |

CMG-22 |

CMG-30 |

CMG-55 |

|

Cleaning media |

Water or cleaning agentia |

||||

|

Operational method |

7" PLC touch screen |

||||

|

Water tank capacity |

40L |

100L/50L + 50L |

100L/50L + 50L |

120L/60L + 60L |

150L |

|

Water tank quantity |

One |

One or two |

One or two |

One or two |

One |

|

Input & output specification |

3/8"*4 |

3/8"*8 |

3/8"*8 + 1"*2 |

1/2"*8 + 1.5"*2 |

1/2"*8 + 2"*2 |

|

Machine power |

1.1KW |

1.5 KW |

2.2 KW |

3.0 KW |

5.5 KW |

|

Power supply |

AC220V 1P+N+ E/AC380V 3P+N+E |

||||

|

Machine dimension |

1000 * 500 * 800mm |

1400 * 500 * 1200mm |

1400 * 500 * 1200m |

1600 * 600 * 1200mm |

Customized |

|

Machine weight |

180Kg |

300 Kg |

320 Kg |

350 Kg |

|

|

Water tank automatic heating |

NO |

Optional |

Optional |

Optional |

Optional |

|

10" touch screen |

NO |

Optional |

Optional |

Optional |

Optional |

|

1000 sets cleaning record |

Optional |

Optional |

Optional |

Optional |

Optional |

|

SUS304 structure |

YES |

YES |

YES |

YES |

YES |

|

SUS316 structure |

Optional |

Optional |

Optional |

Optional |

Optional |

- Mitsubishi PLC touch screen control and full-automatic operation

- Cleaning time, interval time of two direction, pulse time are free to set and control via PLC system

- Pulse blasting cleaning

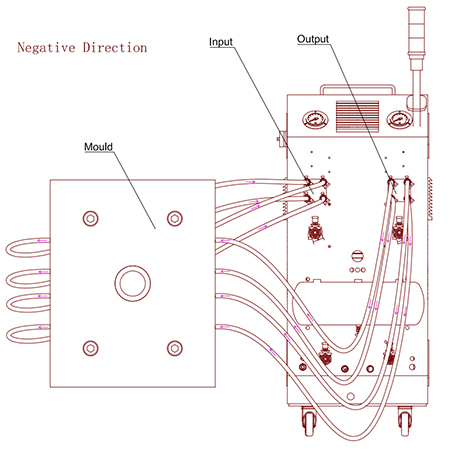

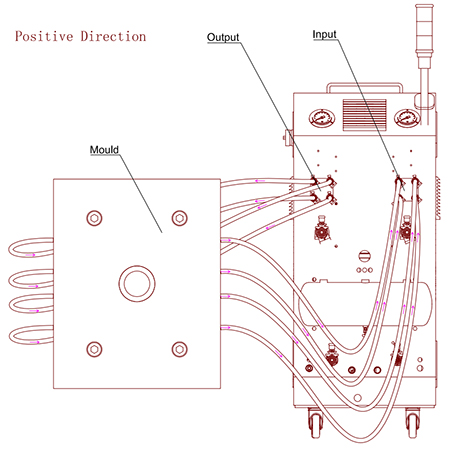

- Positive direction and negative direction cleaning

- Double water tank design, SUS304 structure

- High frequency variable frequency electrolytic cleaning

- leakage testing

- Hydraulic pressure testing

- Air pressure testing

- Pipeline flow test

- Cleaning information record

- Cleaning information record download and save

- Alert information and Solutions

- Automatic drainage

- Automatic replenishment of water tank Water heating

- Multilingual operation systems