This Machine Keeping the strong rigidity, structure symmetry and good stability on the basis of traditional gantry machine foundation frame, introduces the international advanced dynamic rigidity design concept and optimizes the design of the moving parts.This machine has strong rigidity and fast response, which can meet the needs of high-precision aviation parts processing and various high-precision mold processing.

| PROJECT | DESCRIPITION | UNIT | GT-1290 |

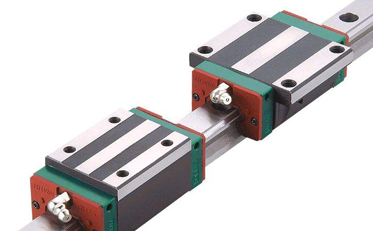

| TRAVEL | XYZ Axis Guiderails type | High Rigidity Roller type Linear Guiderails | |

| X/Y/Z Axis | mm | 1200/900/600 | |

| Distance from Spindle nose to Worktable | mm | 150-750 (Appr.) | |

| Distance between Columns | mm | 1050 (Appr.) | |

| Distance from Spindle nose to Worktable | mm | 220-680 (Appr.) | |

| TABLE | Worktable (LxW) | mm | 1200x900 |

| Max.Loading on Worktable | kg | 1500 | |

| SPINDLE | RPM Spindle Speed | rpm | 20000 |

| TYPE Spindle Taper | HSK-A63 | ||

| FEED RATE | G00 Rapid Feedrate(X/Y/Z Axis) | mm/min | 20000/ 20000/ 10000 |

| G01 Cutting Feedrate | mm/min | 1 – 8000 | |

| PRECISION | Positioning Accuracy/ Re-Positioning Accuracy | mm | 0.008/0.005 |

| OTHERS | Machine Weight | kg | 10000 (Appr.) |

3 Axis standard with Linear Scales,Positioning more accurate.

Laser Tool Probe (Optional)

Humanized design, ergonomics, more convenient operation.

Standard with 21T ATC/Tool Magazine it can perfectly improve the efficiency of machining preparation.

3 Axis Roller Guiderails ,high precision and low friction coefficient, which can reduce Machine creeping phenomenon at low speed, good positioning accuracy and high dynamic response characteristics.

Adopts Built-in type High Speed Motorized Spindle, Max.20000 rpm, best for High Precision & Good Surface Quality Processing.

Previous:CNC Engraving & Milling Machine

Next:no data